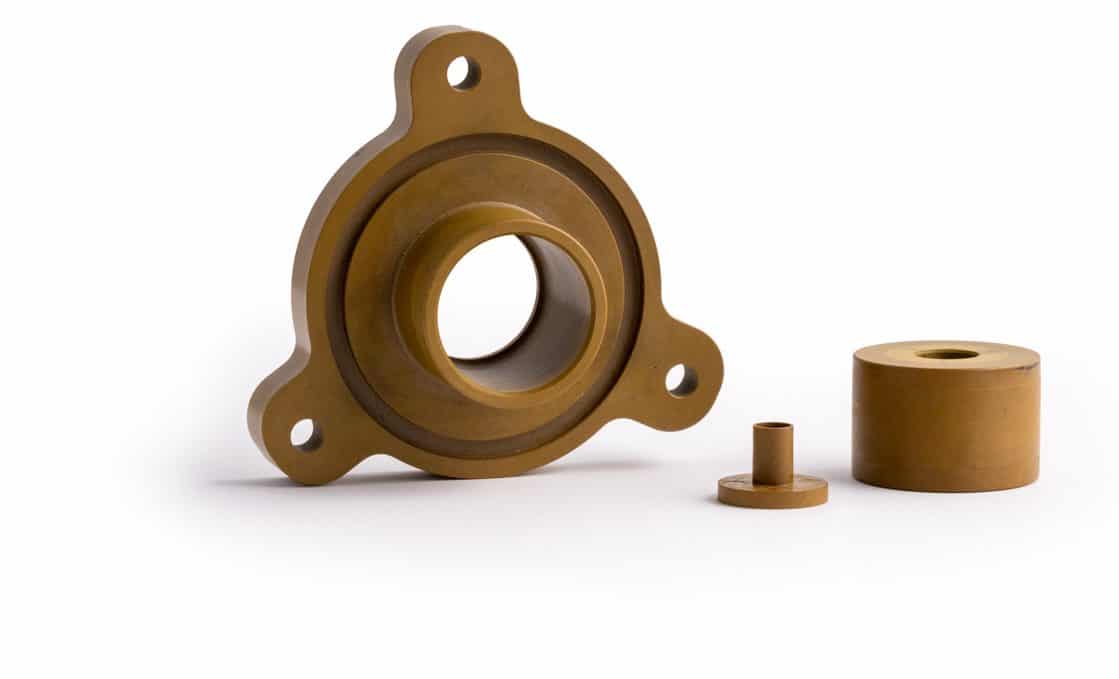

Torlon Plastic

Injection Moldable, Unmatched Strength at High Temperatures

- High performance, melt processable thermoplastic

- An alternative to metal for a variety of components

- Flame retardant, corrosion resistant

Torlon properties

Torlon has more strength at temperatures up to 500°F than other engineered plastics do at room temperature and is more impact resistant at cryogenic temperatures than other high strength polymers. At moderate temperatures it is also extremely resistant to chemicals, including corrosive acids and most organics. It is virtually unaffected by aliphatic, aromatic, chlorinated, or fluorinated hydrocarbons.

In addition to being tough against organic and non-organic chemicals, Torlon plastic is half the weight of aluminum and quieter than metal. These qualities result in a lighter product that can increase mechanical efficiency, making Torlon an idea replacement for metal based components.

Torlon’s properties result from its transformation from a thermoplastic to a cross linked thermoset during an extended curing process. Glass reinforced and carbon fiber reinforced grades offer even greater stiffness and enhanced thermal expansion properties, while still remaining strong at high temperatures. These reinforced grades boast additional properties that are extremely beneficial: lightweight, and chemical resistant.

Types of Torlon plastic

Torlon plastic is available in many forms, and it provides a better solution for a variety of applications.

Torlon 4203 Used for electrical connectors and insulators and other high wear applications due to its high dielectric strength. Torlon 4203 Data Sheet, Torlon 4203L Data Sheet

Torlon 4275 A highly wear and chemical resistant grade, Torlon 4275 is perfect for bearings and thrust washers. Torlon 4275 Data Sheet

Torlon 4301 With a low expansion rate and coefficient of friction, Torlon 4301 is engineered for greater wear resistance and is ideal for reciprocating compressor parts, bearing cages, seals, and non-lubricated bearings. Torlon 4301 Data Sheet

Torlon 4435 Engineered specifically to provide exceptionally low wear in non-lubricated applications, including conditions under high pressure and velocity. Torlon 4435 Data Sheet

Torlon 4601 This grade has been specially formulated to be wear resistant and moldable in tools with minor undercuts, as well as delivering excellent performance in lubricated wear situations. Torlon 4601 Data Sheet

Torlon 4645 Engineered for exceptional resistance to wear, creep, and chemicals in lubricated wear environments. Torlon 4645 Data Sheet, Torlon 4645 Product Data

Torlon 5030 A 30% glass fiber reinforced grade of polyamide-imide resin that offers high strength and exceptional creep resistance. Torlon 5030 Data Sheet

Torlon 7130 A 30% carbon fiber reinforced grade of polyamide-imide resin that has thermal expansion characteristics similar to steel. Torlon 7130 Data Sheet

Industries using Torlon Plastic

Aerospace

Torlon is ideally suited for the aerospace industry due to its stability in both hot and cold environments, resistance to corrosive and oxidizing substances, low wear rates, low friction, ability to withstand high pressure, plus it’s lightweight.

Healthcare

Torlon’s high compressive strength, excellent creep resistance, and low wear rates make it a common choice for peristaltic pump rollers and bushings for prosthetics. Torlon components are also used in analytical instruments and medical devices.

Automotive

Torlon wear and strength properties make it perfect for use in powertrains, cooling and heating systems, engine management systems, oil and fuel circuits, and transmission parts.

Industrial

Put to work in the chemical engineering industry, Torlon’s resistance to various chemicals make it ideal for industrial equipment parts, pipes, pumps, fittings, and valves.

Agriculture

Because it’s half the weight of aluminum but as strong as traditional steels, Torlon is well suited for gears, wear pads, sheaves, housings, plug seals, nuts with gaskets, electrical components, and poppet valves.

Oil & Gas

Torlon is strong enough to handle the high pressure and heat common of oil & gas industry and down hole environments, making it popular for valve seats, connector bodies, seals, flappers, frac balls, and compressor valve components.

Consumer Products

In addition to heavier industries, Torlon is also regularly used in household goods like power and garden tools, textiles and fibers, as well as in various sports and leisure products.

Services we offer for Torlon

Assembly —Fastening, physical joining, adhesives application, sonic welding, hot stamping.

Centerless and Cylindrical Grinding —Tight tolerance diameters / roundness

Contract Manufacturing —Blanket POs, Batch quantities, Just in Time Inventory

Machining — Cutting, Turning, Milling, Grinding.

Plastic Injection Molding —Specialty high performance molding, Plastic injection over molding, and Insert molding.

Prototyping —Low Volume Machining and Molding

Aztec Plastic has extensive experience working with Torlon. We were one of the first companies to ever process the material in the 1970’s when it was originally invented by Amoco. Over the decades, Torlon changed hands in ownership from Amoco to BP to Solvay Advanced Polymers, and Aztec was there during each transition. To this day, we continue to have Approved Vendor Status from Solvay Advanced Polymers for molding and machining Torlon.

We manufacture a wide variety of products for a range of applications using this material. Examples include our Torlon screws for high voltage and thermal isolation, rectifiers, and high and low voltage inverter parts, and Torlon poppets and spools fighting leakage problems in hydraulic power systems.