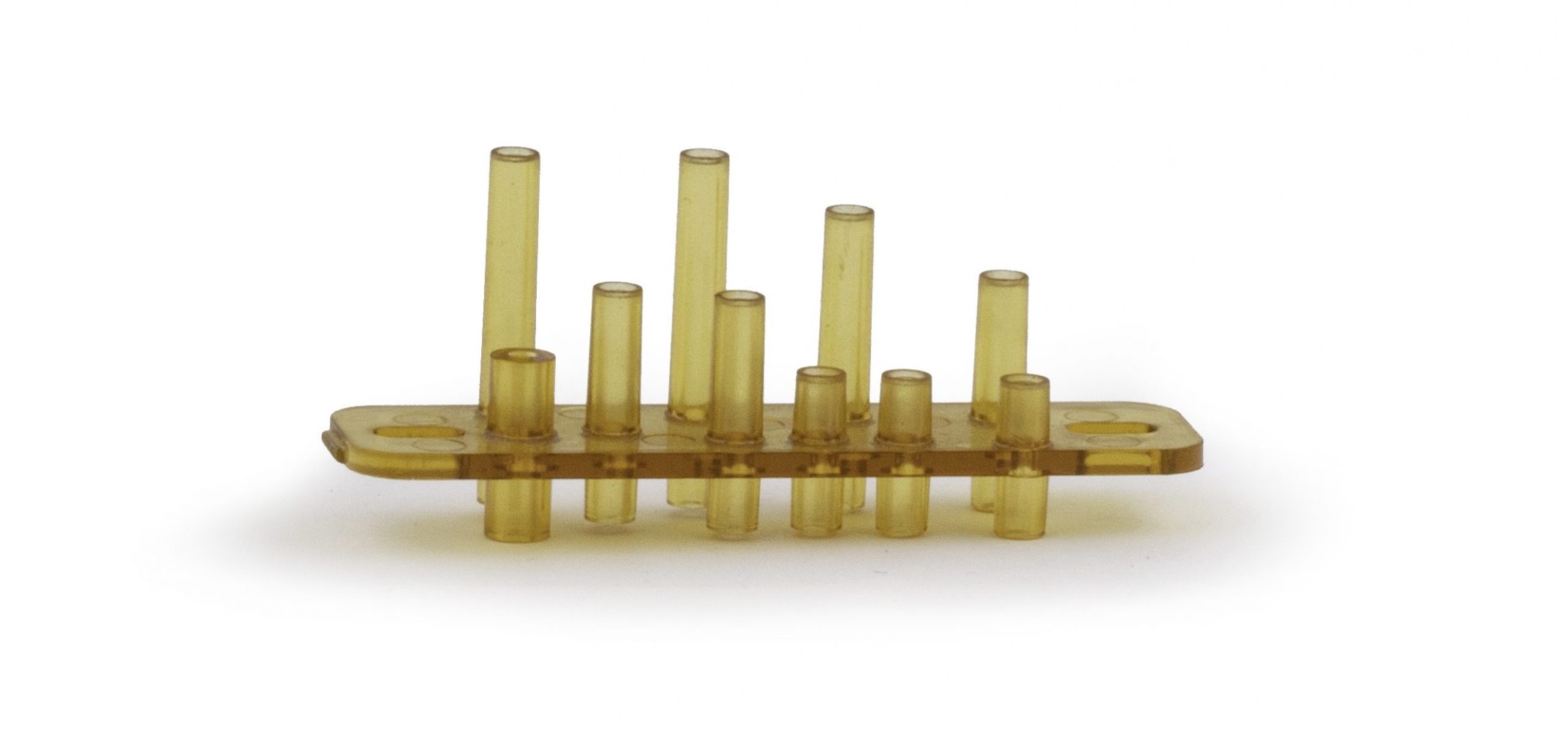

Ultem Plastic Is Ideal for High Temperature Applications

It is resistant to heat, flames, and many chemicals

- High strength, durable thermoplastic

- Capable of being molded and machined to precise specifications

Ultem plastic or polyetherimide is a semi-transparent, strong thermoplastic material engineered to operate in very high temperatures. It has a continuous-use max temperature of 340° Fahrenheit and is resistant to hot water, steam, flames, and UV rays. Additionally, polyetherimide has excellent electrical properties, including good arc resistance and the highest dielectric strength of any thermoplastic material.

Ultem is available in various grades in sheet, rod, tube, film, and injection molded and machined components.

Uses of polyetherimide

Its heat and electrical characteristics make Ultem ideal for a wide variety of injection molded and machined components. It is commonly used for the following applications:

- Electrical housings

- Semiconductor parts

- Electrical insulation

- Aircraft components

- Medical device parts

- Microwaves & manifolds

Other advantages of using polyetherimide

In addition to its ability to operate in high temperatures and its electrical properties, Ultem does not break down in contact with water or many acidic solutions. It can also tolerate repeated steam sterilization processes, making it ideal for use in reusable medical devices that require autoclaving sterilizing methods. Polyetherimide resins also retain their strength and resist cracking when exposed to automotive and aircraft fluids, aliphatic hydrocarbons, alcohols, acids, and weak aqueous solutions.

Because Ultem plastic is highly processable, it can be used in a variety of processes, including extrusion, thermoforming, injection molding, and machining. The result is a component that meets your exact specifications.

Services we offer for polyetherimide

Assembly —Fastening, physical joining, adhesives application, sonic welding, hot stamping.

Centerless and Cylindrical Grinding —Tight tolerance diameters / roundness

Contract Manufacturing —Blanket POs, Batch quantities, Just in Time Inventory

Machining — Cutting, Turning, Milling, Grinding.

Plastic Injection Molding —Specialty high performance molding, Plastic injection over molding, and Insert molding.

Prototyping and 3D Printing —Low Volume Machining and Molding