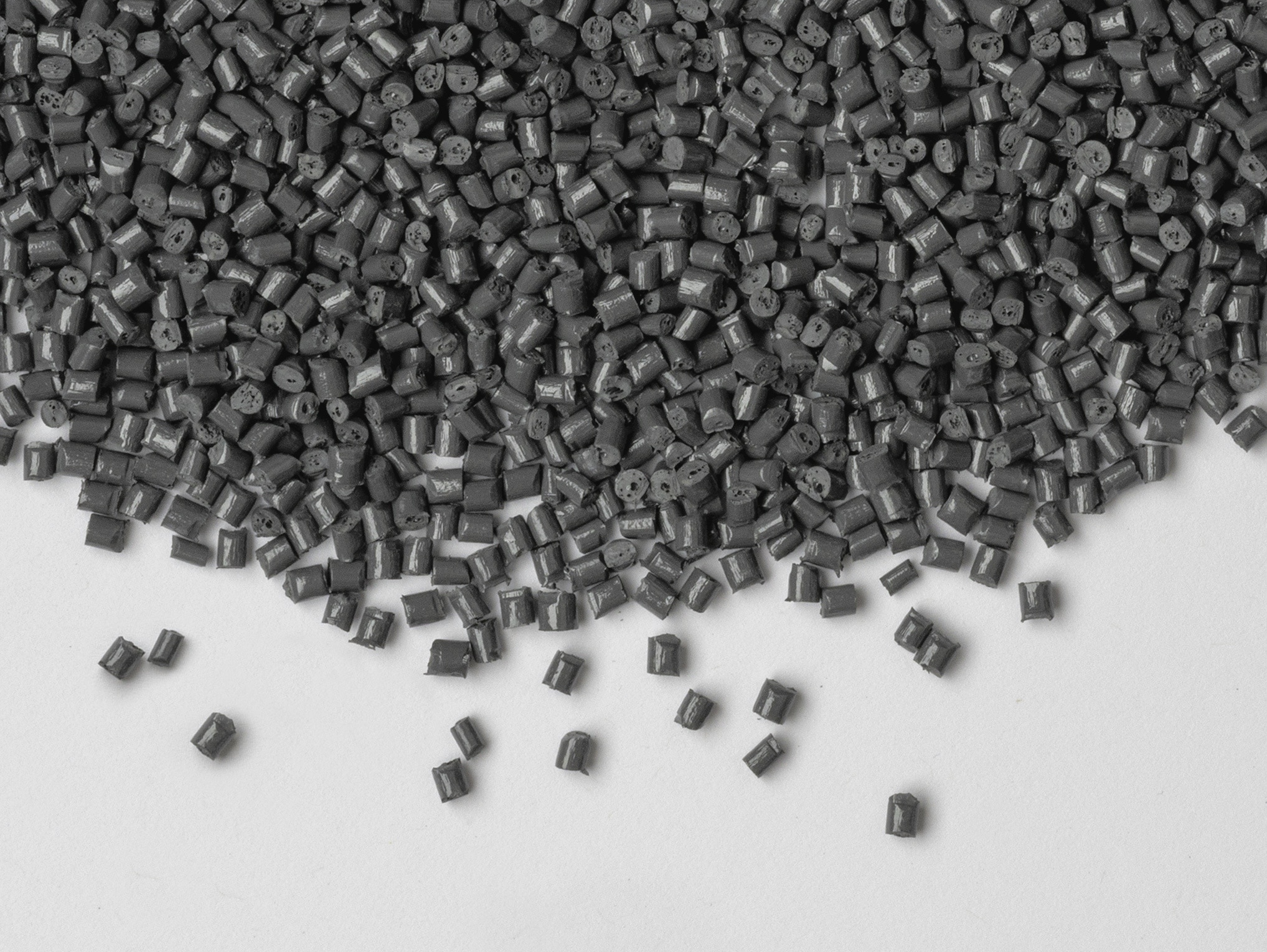

Delrin® Plastic

Excellent for electrical, engine, and medical components

- Tough, durable plastic

- One of the most widely used thermoplastics

- Excellent wear properties

Why use Delrin plastic

Frictional characteristics – Delrin has a low coefficient of friction, especially in wet or moist environments, which helps reduce the wear rates for the parts and components made from it.

High strength – Delrin is crystalline and does not become brittle, even when exposed to very high temperatures or to other harsh conditions. It provides the rigidity, toughness, and strength required by automotive, electrical, medical, and other components.

Low moisture – Delrin plastic absorbs only minimal amounts of moisture, making it ideal for parts operating in wet or damp conditions.

Easy to fabricate – Delrin is typically available in rods or sheets that can be easily machined, injection molded, and formed to almost any desired specification. Any machining tool that is capable of high speed without vibration can be used in the development process.

Applications of Delrin

We use Delrin for metal replacement in a wide range of industrial and mechanical components. With the advanced injection molding and machining capabilities at Aztec Plastic, we engineer:

- Engine gears, bearings, valves, springs, cams, and fan wheels

- Pump and valve components regularly exposed to moisture

- Ski bindings

- Electrical insulators

- Surgical instruments

- Food conveyors

- And more!

Services we offer for Delrin Plastic

Assembly —Fastening, physical joining, adhesives application, sonic welding, hot stamping.

Centerless and Cylindrical Grinding —Tight tolerance diameters / roundness

Contract Manufacturing —Blanket POs, Batch quantities, Just in Time Inventory

Machining — Cutting, Turning, Milling, Grinding.

Plastic Injection Molding —Specialty high performance molding, Plastic injection over molding, and Insert molding.

Prototyping—Low Volume Machining and Molding