Reduce Your Manufacturing Costs with Aztec Plastic

We provide high quality plastic parts on schedule, every time- We complete injection molding, machining, and other secondary activities in house

- Our deliveries are always on time, as promised

- Excellent quality parts and components

- All our plastic products are made in the USA

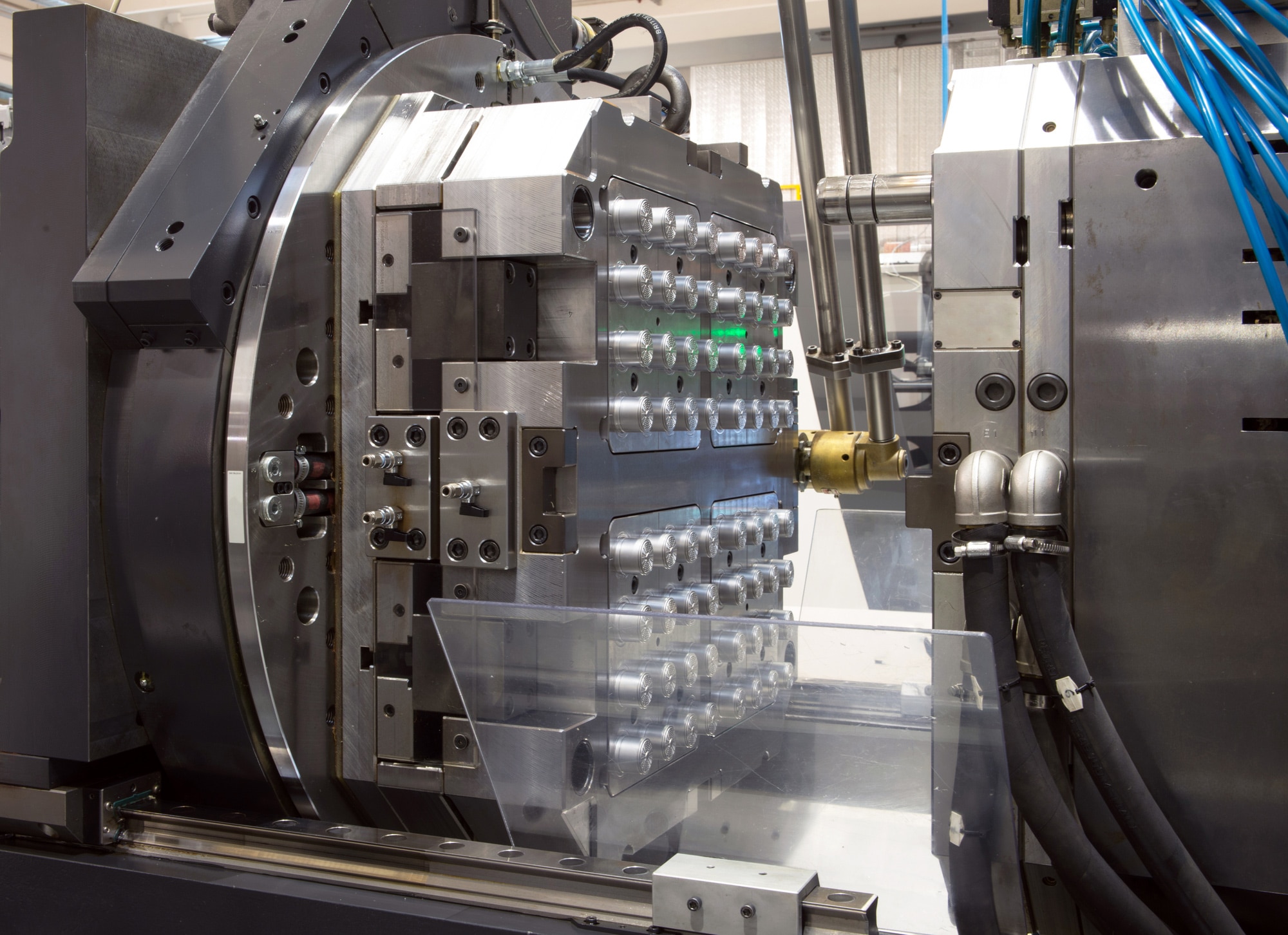

Aztec Plastic has been in business for over 50 years and has been at the cutting edge of plastic injection molding since its beginning. We produce high quality, precisely engineered plastic components to your exact specifications that outlast and outperform metal and other traditionally used materials. Our team of quality control experts are dedicated to ensuring your prototypes and finished products meet your exact requirements.

For the full range of services offered, from injection molding to secondary services, Aztec Plastic builds the entire product in house, ensuring projects aren’t delayed by sub contractors or foreign manufacturers. Our team delivers your plastic parts and products on time, every time.

We handle your entire project

We specialize in metal replacement

The materials we work with:

- Polycarbonate

- Polyethylene

- Polypropylene

- Duradex

- Valox

- Ketaspire

- Avespire

- Primospire

- ABS

- PPSU

- LCP

- PPS

- Valox

- Xenoy

- Stamax

- Noryl GTX

And many other ultra engineering grades that fall under the umbrella for metal replacement materials!

Certifications & Designations

ISO 9001:2015

AS9100 Rev D

NIST 800 -171

ITAR Registered

Cage Code: 4Y054

Woman Owned Business

Torlon Processor

PPAP Levels 1-4 / DPAR

Society of Plastic Engineers

WBENC

Industries

Agriculture

Construction

Off Highway

Automotive

Aerospace

Department of Defense

Electronics

Non-invasive Medical

Capabilites

Injection Molding

Machining

Secondary

Centerless grinding

CNC machining

Assembly

EAU of 5 pieces to 10 million pieces

Aztec Plastic Company

Chicago, Illinois 60612