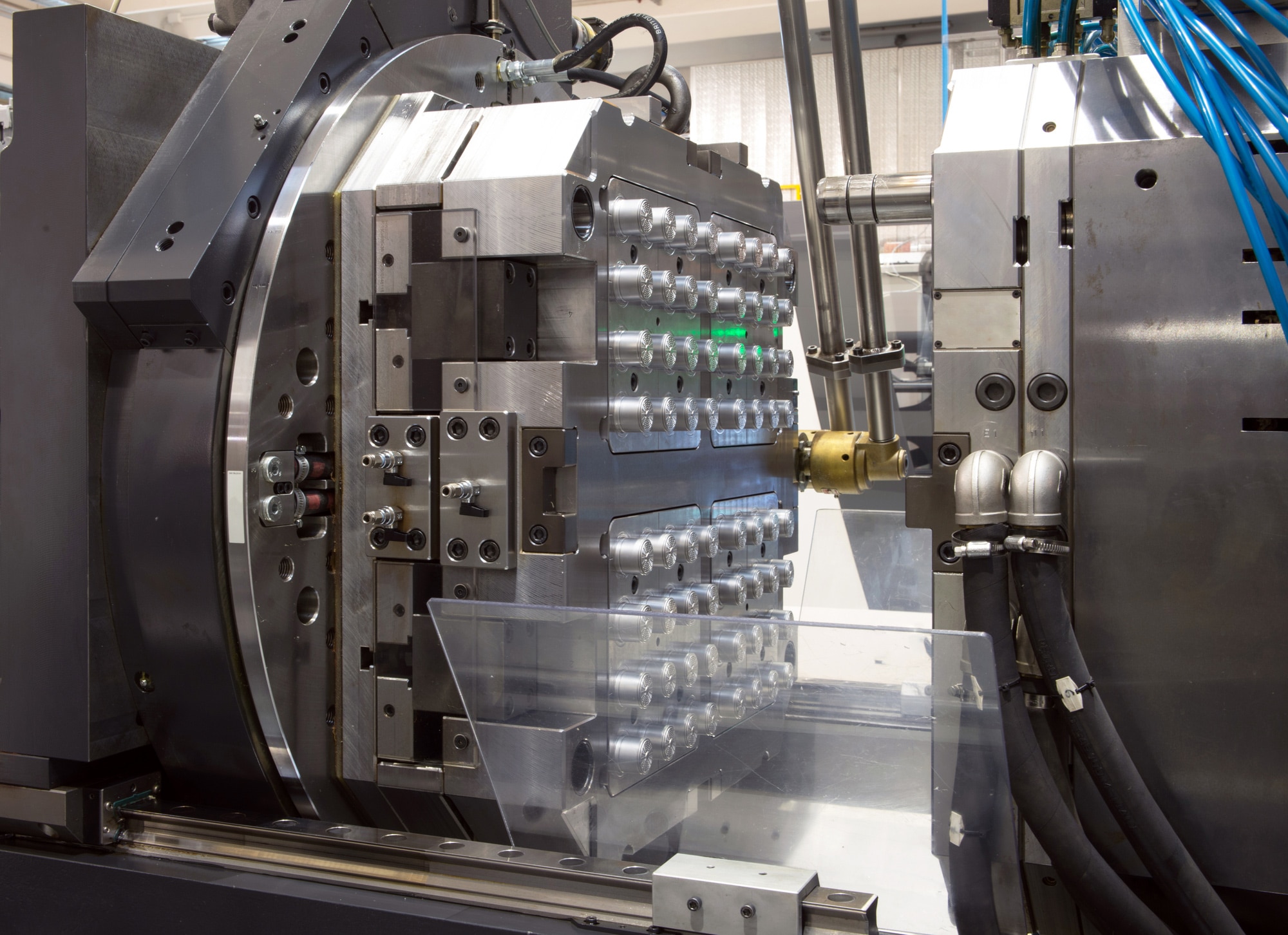

When it comes time to switch plastic injection molders, it can be a daunting task. For big operations, transferring molding tools can mean moving millions of parts at the cost of millions of dollars. The key to doing it successfully is to carefully plan, communicate with all parties, and invest the necessary time and money to do it right.

Why move your plastic injection molding tool?

There are many reasons that a company would want to transfer their tooling assets from one molder to another. The primary ones are to realign competencies, meet new requirements, or switch from an unproductive relationship. Plus, the transfer is an opportunity for you or a third party to complete an exhaustive evaluation of the condition of the mold.

How to transfer your mold

The primary issue for businesses that decide to move their mold assets is a delay in production. You also have to worry about potentially damaging equipment and materials. To help you avoid both of these challenges, you should follow several best practices to make the process go smoothly.

- Open communication – All parties to the mold transfer must fully discuss the process, agree what is to be done, and outline who is responsible for what.

- Review the condition of the current tool – It’s critical to assess the mold tool at the current location, so you know if there are any damages or issues before the move takes place.

- Stock up on inventory – Transferring your mold tool will inevitably cause some production disruptions. To combat these, you should manufacture a sufficient number of products to cover any gap in manufacturing.

- Evaluate the tool at the new location – Once the mold tool is moved to and set up at the new molding site, verify that it meets the necessary specifications.