Material Library / Datasheets

A few of the materials we work withAmodel A – 8930 HS -

A 30% glass fiber filled, reinforced polyphthalamide (PPA) plastic designed to work in automotive electrical components. This heat stabilized plastic resin is strong and has exceptional creep resistance, high tensile strength, and low moisture absorption.

Amodel® A -1145 HS -

A 45% glass fiber filled polyphthalamide thermoplastic resin that is stiff, high strength, and great for water environments. Other characteristics are exceptional creep resistance, high chemical resistance, and low moisture absorbance.

Amodel® A – 1640 HS -

A 40% long fiber, carbon fiber filled PPA high temperature plastic resin with high stiffness and strength. Other characteristics are creep resistance, fatigue resistance, low shrinkage, and electrical conductivity. Ideal for the automotive, marine, industrial, and consumer products industries.

Amodel® A – 8950 HS -

A 50% glass fiber filled PPA plastic resin with excellent creep resistance, high tensile strength, low moisture, high strength, and good stiffness. Amodel AE-8950 is ideal for use in modern automotive electrical systems.

Amodel® A -1625 HS -

A 25% carbon fiber and glass fiber filled PPA thermoplastic resin. It is specially formulated for applications requiring the dissipation of static charge and is well suited for fuel system components that need low permeation, low swell, and high thermal resistance.

Amodel® LF-1630 L NT-7 -

A 30% long fiber, carbon fiber filled PPA high temperature material with high stiffness and strength. Other characteristics are creep resistance, fatigue resistance, and low shrinkage.

Amodel® LF-1930 FW HS BK545-8 -

A 30% long fiber, glass fiber filled PPA high-temperature material with high stiffness and strength. Other characteristics are creep resistance, fatigue resistance, and low shrinkage.

Amodel® LF-1950 HS BK 324 -

A 50% long fiber, glass fiber filled PPA high temperature material with high stiffness and strength. Other characteristics are creep resistance, fatigue resistance, and low shrinkage.

Amodel® Polyphthalamide (PPA) -

An easy reference tool for designers and fabricators interested in Amodel PPA as a solution for their material. See the property data for select grades as well as part design and processing recommendations for each polyphthalamide grade.

Semilon PK4000 -

A high temperature PEEK plastic that resists water, radiation, and chemicals, making it ideal for a wide variety of industrial components and environments.

Semilon PK5000 -

A high temperature PEEK plastic that resists water, radiation, and chemicals, along with high molecular weight and high ductility.

Semilon PKCC30 -

A high temperature PEEK plastic that resists water, radiation, and chemicals. This PEEK grade is 30% ceramic filled.

Semilon PKCF30 -

A high temperature, 30% carbon filled PEEK plastic that resists water, radiation, and chemicals.

Semilon PKFC30 -

A high temperature PEEK plastic that resists water, radiation, and chemicals.

Semilon PKGF30 -

A high temperature, 30% glass filled PEEK plastic that resists water, radiation, and chemicals.

Torlon® 4203 -

An unreinforced, lubricated, pigmented grade of polyamide-imide (PAI) plastic resin for extrusion. It’s ideal for thrust washers, spline liners, valve seats, bushings, bearings, wear rings, cams, and other applications that require high strength at high temperatures.

Torlon® 4203L -

Unreinforced, lubricated, extrusion grade of polyamide – imide (PAI) plastic resin with the highest strength and stiffness of all polymers. It has exception resistance to wear, creep, and chemicals, and is used for thrust washers, spline liners, valve seats, bushings, bearings, wear rings, cams, and more.

Torlon® 4275 -

A wear resistant, high strength grade of Torlon, this thermoplastic is great for bearings and thrust washers, with exceptional resistance to creep and chemicals.

Torlon® 4301 -

A wear resistant thermoplastic that offers high flexural and compressive strength with a low coefficient of friction in high velocity, high pressure, and high temperature conditions.

Torlon® 4435 -

Specifically designed to provide exceptionally low wear performance in non-lubricated applications even at high pressure and velocity (PV) conditions. Torlon 4435 is a thermoplastic that is ideal for use in thrust washers, seal rings, sliding vanes, bobbins, bushings, pistons, and more.

Torlon® 4601 -

A specialty wear resistant grade of polyamide-imide (PAI) thermoplastic that has been formulated to be moldable in tools with minor undercuts and provide very good performance in lubricated wear applications.

An injection moldable, wear resistant grade of polyamide-imide (PAI) thermoplastic, has been formulated to give outstanding wear resistance in lubricated wear applications. Torlon 4645 is ideal for use in clutch rollers, pistons, bushings, bobbins, seal rings, and more.

Torlon® 5030 -

A 30% glass fiber reinforced grade of polyamide-imide (PAI) thermoplastic resin that offers high strength, exceptional creep resistance, and has thermal expansion characteristics similar to aluminum, making it ideal for metal replacement. Torlon 5030 is used in electrical connectors, switches, and relays.

Torlon® 7130 -

A 30% carbon-fiber reinforced grade of polyamide-imide (PAI) plastic resin that has thermal expansion characteristics similar to steel. Torlon 7130 is used for metal replacement, sliding vanes, aerospace parts, impellors, shrouds, pistons, housings, and more.

Torlon® PAI -

Torlon polyamide-imide (PAI) has the highest strength and stiffness at elevated temperature of any thermoplastic commercially available. See why its properties make it ideal for use as metal replacement in industries ranging from automotive to aerospace.

Torlon® PAI Design Guide -

Torlon polyamide-imide (PAI) polymers perform under conditions generally considered too severe for thermoplastics. This design guide lays out the properties and uses of the various Torlon polymers.

ULTEM™ Resin 1000 -

An unreinforced general purpose ULTEM plastic grade offering high heat resistance, high strength and modulus and broad chemical resistance up to high temperatures.

ULTEM™ Resin 2300 -

A 30% glass fiber filled, standard flow polyetherimide ULTEM plastic. It is ECO Conforming and has UL94 V0 and 5VA, NSF 51 listing, WRAS certification, and KTW certification in recognized colors.

ULTEM™ Resin 2400 -

A 40% glass fiber filled, standard flow polyetherimide ULTEM plastic. It is ECO conforming and has UL94 V0 and 5VA listing, and WRAS certification in recognized colors.

Victrex® -

Victrex provides exceptional performance over a wide range of temperatures and extreme conditions.

VICTREX® PEEK 150G / 151G -

VICTREX is a semi crystalline, FDA food contact compliant, high performance thermoplastic material with depth filtered granules for injection molding.

VICTREX® PEEK 150G903 BLACK -

A black semi crystalline, FDA food contact compliant, high performance thermoplastic material with depth filtered granules for injection molding.

VICTREX® PEEK 450G -

A high performance thermoplastic, VICTREX PEEK 450G is highly resistant to aggressive and corrosive chemicals.

VICTREX® PEEK 450G903 BLACK -

A black, high performance PEEK thermoplastic material that is chemically resistant to aggressive environments and suitable for sterilization for medical and food contact applications.

VICTREX® PEEK 650G -

High performance thermoplastic material suited for applications requiring higher strength and stiffness as well as enhanced ductility. VICTREX PEEK 650G is suitable for sterilization in medical and food contact applications.

VICTREX® PEEK 90G -

VICTREX PEEK 90G has high strength, stiffness, and good ductility properties. It is ideally suited for complex geometries with thinner cross sections or longer flow lengths. It is suitable for sterilization for medical and food contact applications.

Vydyne® 21 SPF -

A general purpose PA66 resin, Vydyne 21 SPF is designed principally for plastic injection molding fabrication. It is high strength, has a high melt point, and is resistant to many chemicals, machine and motor oils, solvents, and gasoline.

Vydyne® 21SPF BLK -

A general purpose PA66 plastic resin, Vydyne 21 SPF BLK offers high strength, rigidity, good toughness, a high melt point, good surface lubricity, abrasion resistance, and resistance to many chemicals.

Vydyne® R513H BK02 -

A black, high-flow, 13% glass fiber reinforced, heat stabilized PA66 plastic resin. Vydyne R513H BK02 is lubricated for machine feed, flow, and mold release applications in the automotive industry.

Case Studies:

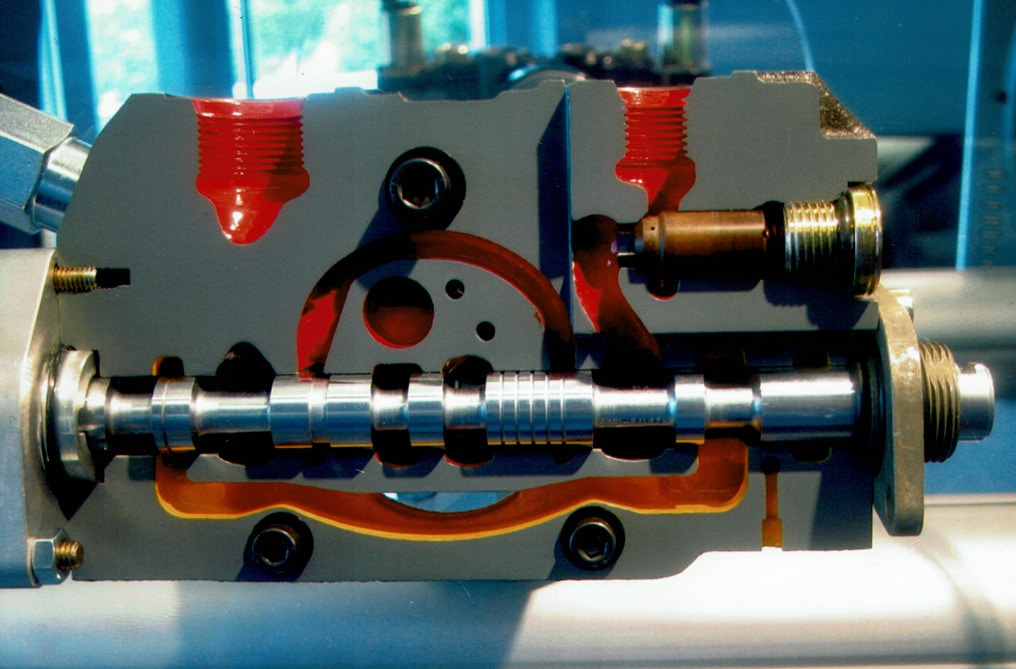

Aztec Poppets Case Study

Aztec Plastic uses Torlon poppets and Torlon spools to reduce leakage in hydraulic systems and create longer lasting components compared to metal.

Useful Information:

IMEC Partners with Illinois Plastic Injection Molding Company to Organize the Workplace and Improve Processes

IMEC partners with Illinois plastic injection molding company, Aztec Plastic, to organize the workplace and improve processes