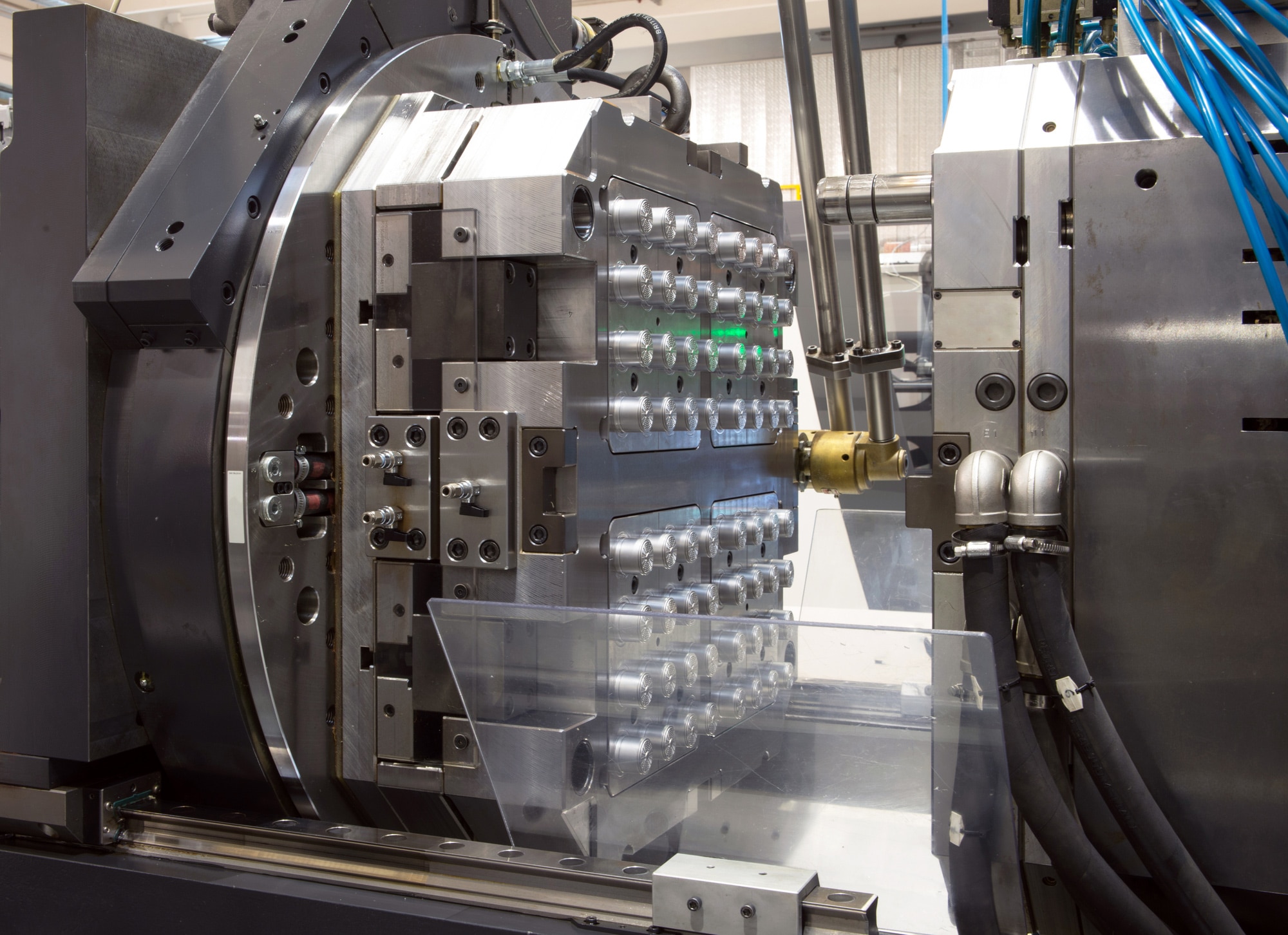

IMEC Partners with Illinois Plastic Injection Molding Company to Organize the Workplace and Improve Processes

Aztec Plastic Company implements 5S Workplace Organization and Kaisen to eliminate wastes, improve productivity and efficiency, and boost employee satisfaction.

Read More...

High Performance Plastics in Fluid Power Systems

Aztec Plastic has been combating leakage problems in poppets and spools by using TORLON polyamideimide from Amoco Polymers, with its customers seeing dramatic results.

Read More...

Delrin vs Acetal

Although Delrin plastic is a type of acetal and they are both used for similar applications, there are some key differences between the two.

Read More...

Transferring Your Plastic Injection Molding Tool

When it comes time to switch plastic injection molders, it can be a daunting task. Here we discuss why you might need to move your plastic injection molding tool, how to do it professionally, and a tooling transfer checklist that you can download for a successful move.

Read More...

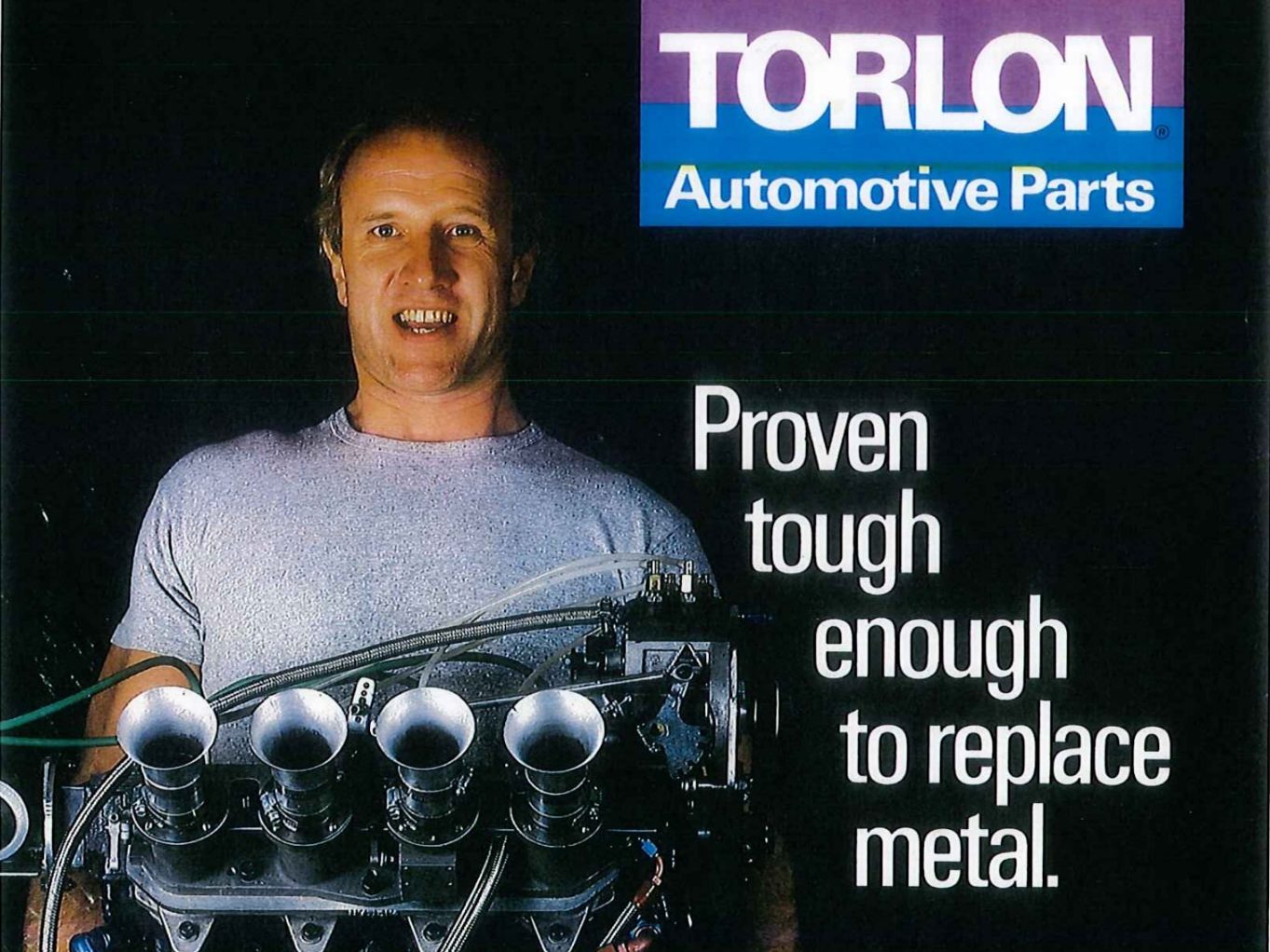

The Story of the World’s First Torlon Plastic Engine

Amoco built the world's first racecar engine with parts made of injection molded Torlon plastic in 1984.

Read More...

Plastics in Automotive Applications

The use of plastics in the automotive industry is on the rise. According to the American Chemistry Council, more than 5.7 billion pounds of plastics are employed for automobile production annually. Why? Because high performance plastics have environmental and economic advantages.

Read More...

Polymer Components for Fluid Power Systems

In order to keep pace with increasing demands, the internal components of fluid power systems are also changing. Whereas steel poppets and spools were once sufficient for most hydraulic and fluid power applications, new parts made of advanced polymers are delivering superior performance and service.

Read More...

Torlon: Your Next Solution

With its exceptional mechanical strength and durability, Torlon plastic is suitable for a wide range of high stress situations and metal replacement. Today, it’s found in the aerospace industry, automotive industry, electrical equipment, manufacturing equipment, and more.

Read More...

Plastics in the Aerospace Industry

Torlon aircraft components are becoming more and more popular with manufacturers because of its exceptional mechanical strength, low thermal expansion, and excellent creep, thermal, chemical, and flame resistance.

Read More...

Plastics in the Medical Industry

Plastics in the medical industry have helped make products safer, more affordable, and innovative. Plastics help maintain a sterile environment, improve the patient experience, and allow for less expensive, more complex design flexibility.

Read More...