Injection Molding for the Healthcare and Pharmaceutical Industry

Cutting edge materials, precision process

- Injection molding, contract manufacturing, plus assembly and kitting

- Products range from hospital equipment to disposables

Aztec Plastic manufactures components and devices using medical grade plastic materials that are durable, reliable, and meet FDA regulations. Manufacturing hospital and surgical equipment, disposables, and other medical devices, we use the latest technologies and processes to develop products that both enhance and save lives.

Aztec Plastic offers a strategic advantage to our customers within the healthcare industry through innovative ideas and solutions. For over 50 years, we’ve manufactured products using FDA approved high-engineered plastics and resins like Torlon, Delrin, Acetal, Peek and Ultem, to name a few.

Why use plastic injection molding in the medical industry

The medical plastic injection molding process is cost effective and perfect for high volume production runs and components that require consistency and tight tolerances. Due to their versatile nature and the ability to be combined with metal, medical grade plastics have become the preferred material for a wide variety of electronic medical devices. Medical plastic injection molding delivers several advantages:

- Improved ergonomics

- Reduced weight

- Increased functionality

- Lower cost

- Decreased burden of sterilization

Medical devices that are manufactured from injection molded plastic have led to a reduction in medical costs and infectious diseases, as well as improvements in pain management. Plastic injection molding directly contributes to greater patient safety and the ability of doctors to save more lives.

Medical devices utilizing plastic injection molding

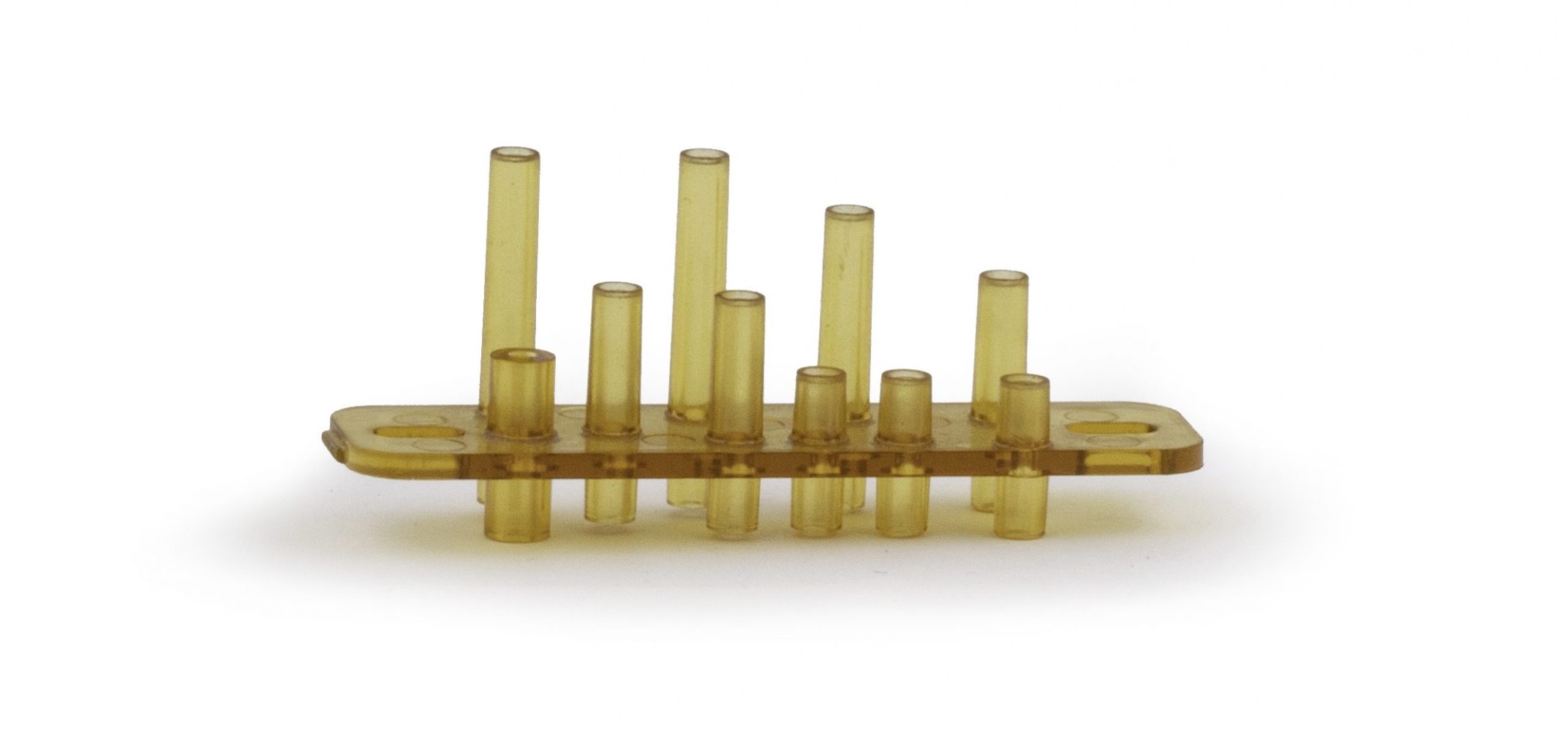

Using injection molding, Aztec Plastics manufactures delivery devices, housings, and other parts for various types of instruments, including:

- Implants

- Medical enclosures

- Medical knobs

- Tubes

- Spinal implants

- Knee and hip replacement components

- Trauma fixation devices

- Dialysis pump filters

- Spiked washers

- Centrifuges and disc filters

- And more!

PEEK for medical devices

Consistent quality

From 1 piece to 10+ million pieces, Aztec has you covered

- Prototype stage and all you need is a couple of parts

- Low volume projects, 50-5,000 pieces

- Multiple programs, but low volume

- High volume contract manufacturing project with millions of parts needed annually

Is Aztec a good fit for your company?

- FDA approved products

- Prioritize patient safety

- High and low volume production needs

- Aim to reduce medical costs

- Looking for a reliable supply manufacturer