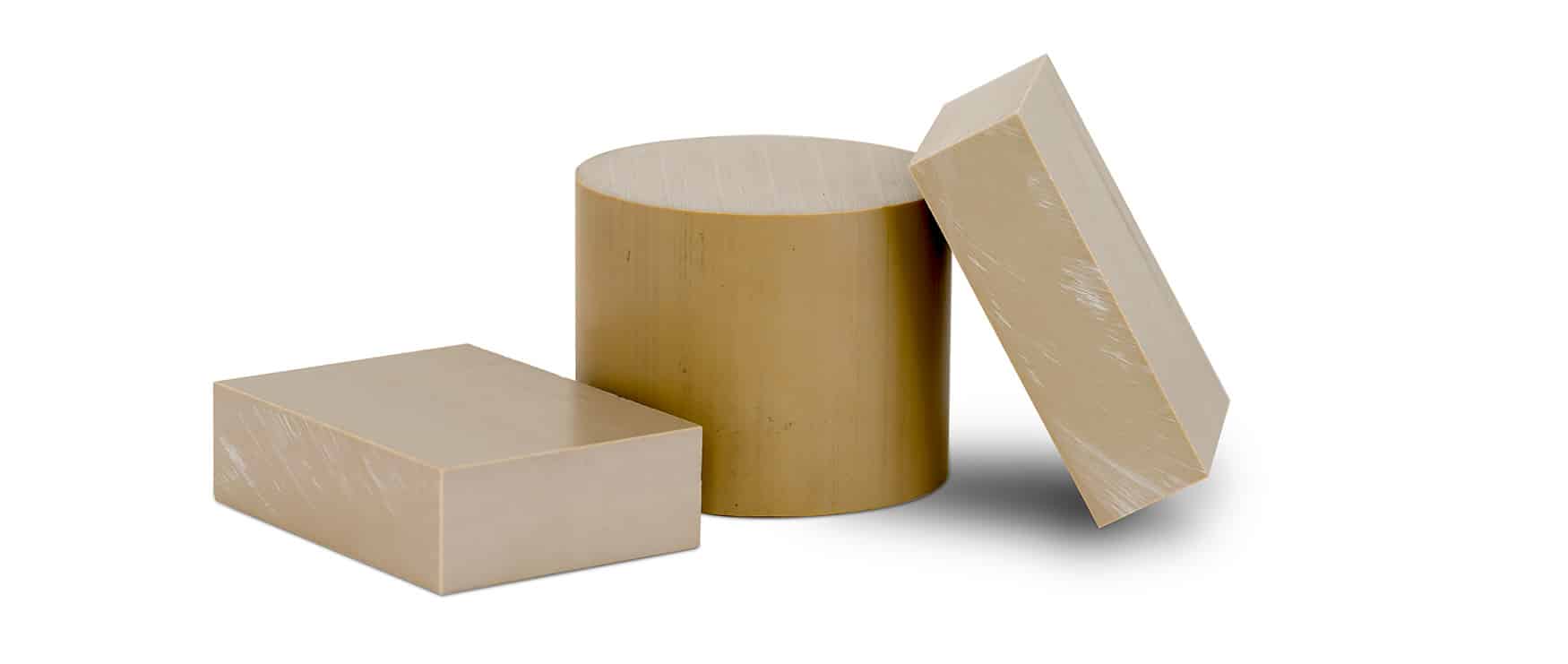

PEEK Plastic

High strength for a variety of industries

- Industrial strength thermoplastic

- An alternative to metal for a variety of components

- Chemical and temperature resistant

PEEK plastic injection molding

PEEK plastic injection molding is used for creating a wide range of components in the aerospace, oil and gas, food and beverage, and pharmaceutical industries. The high strength, anti-friction, chemical and high temperature resistant properties of PEEK plastic make it ideal for parts that need to withstand a lot of wear, like bearings, pumps, valves, and more. With our advanced injection molding and machining capabilities, we can manufacture precise components with extremely tight tolerances.

Key benefits of PEEK plastic

- The chemical resistance of PEEK plastic is similar to that of PTFE. Unlike PTFE, however, the PEEK plastic can be used in more demanding applications where high strength, and anti-wear properties are required.

- Even at high temperatures, PEEK plastic maintains its shape, allowing it as an option in a variety of new environments that other thermoplastics would not be compatible with.

- PEEK plastic is one of the few plastics that can be used in medical implants. Unlike other plastics, which may be rejected by the body or may not meet the stringent wear requirements for medical devices, PEEK plastic has been used in many medical applications, including spinal implants.

What makes PEEK plastic unique

The combination of organic and chemical resistance with some of the highest mechanical strength of any engineered plastics make PEEK extremely versatile. Even when used at 260 degrees Celsius for 5,000 hours PEEK maintains nearly the same strength as it has in its initial state, plus excellent thermal stability. Additional properties that allow PEEK to be used in such a wide variety of applications throughout various industries include resistance to seawater, low VOC (volatile organic compound) content, and high levels of radiation resistance.

Uses of PEEK plastic

In addition to being used for bearings, pumps, valves, medical devices, and medical implants, PEEK is also widely incorporated into manufacturing the following types of products:

- Semiconductor machinery components

- Aerospace parts

- Bushings, seals, and back up rings

- Vacuum wand handles

- Down hole electrical connectors

- Food processing machinery components

PEEK materials can comply with numerous quality standards, allowing us to use them in a wide variety of industries.

- Food: FDA, (EC) No. 1935/2004, (EU) No. 10/2011, China food contact regulation

- Medical: ISO 10993, USP Class VI

- Aerospace: FAR 25.853, MIL-P-46183

- Oil and Gas: ISO 23936-1, NORSOK M-71OC

PEEK plastic machining

Machining PEEK plastic can be difficult, as its unique properties require special handling to minimize cracks from the heat and internal stress during processing. At Aztec Plastic, we determine whether PEEK is best for your product, then use our highly advanced injection molding, 3D printing, grinding, and decorative capabilities to create a finished part or component, built to your exact specifications. Our team of plastic experts use the latest, cutting edge PEEK machining practices to ensure your product is perfect every time.

Services we offer for PEEK plastic

Assembly —Fastening, physical joining, adhesives application, sonic welding, hot stamping.

Centerless and Cylindrical Grinding —Tight tolerance diameters / roundness

Contract Manufacturing —Blanket POs, Batch quantities, Just in Time Inventory

Machining — Cutting, Turning, Milling, Grinding.

Plastic Injection Molding —Specialty high performance molding, Plastic injection over molding, and Insert molding.

Prototyping —Low Volume Machining and Molding