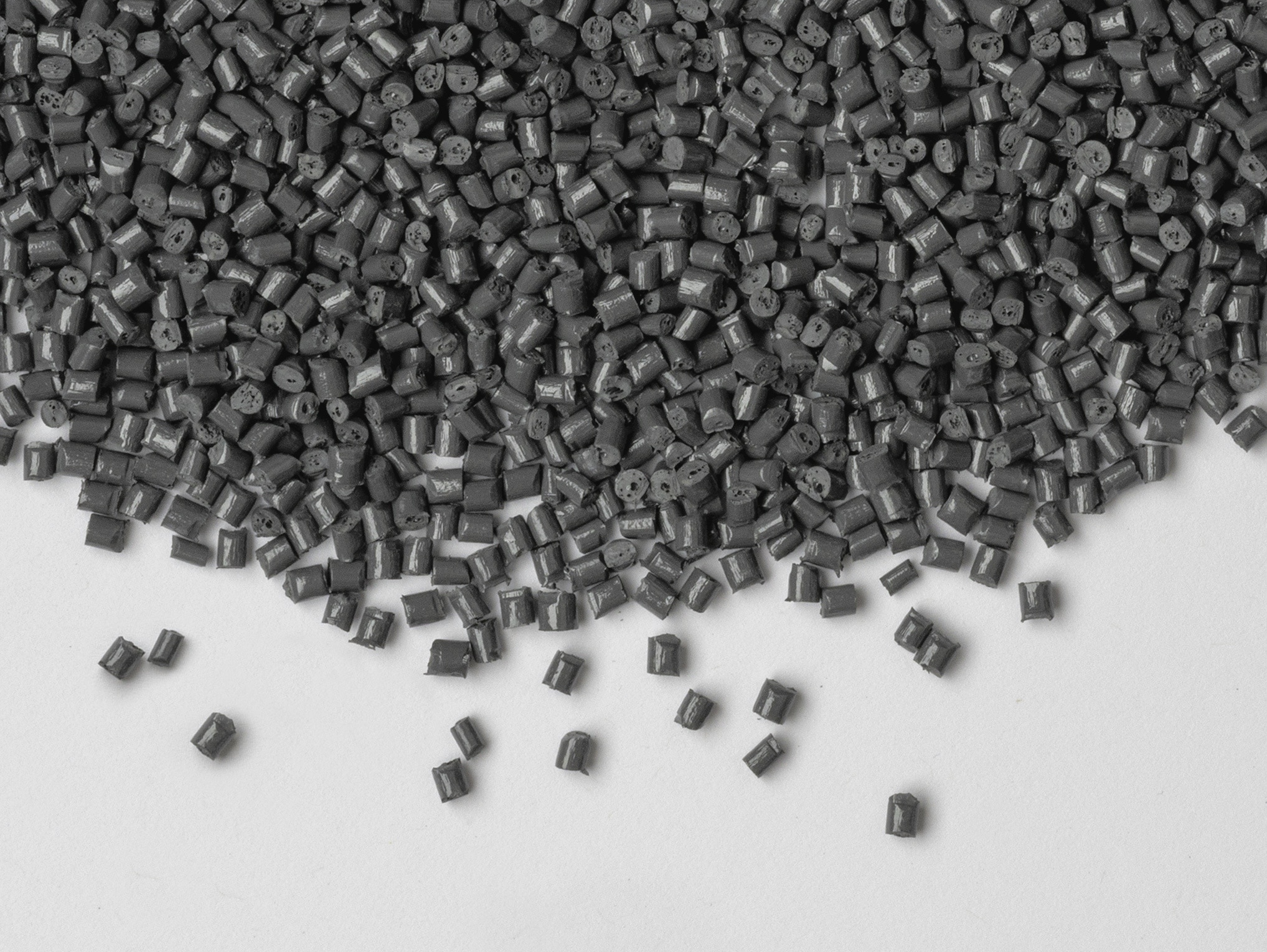

The Industrial Plastics We Work With

High strength, durable, chemical resistant materials

- Wide variety of thermoplastics and thermosets

- Machining and secondary services available

PEEK Resins are part of a family of Semi-Crystalline thermoplastics that are high performance, high temperature resistant materials. They are used for various components and applications within the aerospace, medical, military, electronics, industrial, and filtration markets. This engineered resin is ideal when thermal, chemical and combustion properties plus wear resistance are critical for performance.

Torlon is an amorphous polymer that has exceptional mechanical, thermal, chemical, and wear resistant properties. It is the highest performing thermoplastic that is still melt processable, which makes it the best polymer to select for many applications.

PVC Polyvinyl Chloride is an industrial plastic that has many adaptable properties and is used widely across many industries, including medical, consumer products, construction, industrial and electrical, as examples. It is available in rigid and flexible forms and is often used to replace materials like glass and rubber.

Nylon is a typical engineering plastic that features high levels of toughness, heat resistance, and oil resistance. Used chiefly in automobile and mechanical parts, connectors, and electronics components, it is also common in packaging and construction materials.

Polyethylene is the thermoplastic polymer that is most often used. It is categorized into several major compounds, with the most common types being LDPE, LLDPE, HDPE, MDPE.

HDPE is a variety of polyethylene that is frequently used. It is known for its large strength-to-density ratio and its resistance to many solvents.

LDPE is another commonly used variety of polyethylene and is a very flexible material with unique flow properties.

Polybutylene terephthalate (PET) is a highly flexible material with good dimensional stability and resistance to impact and many solvents.

Polybutylene terephthalate (PBT) has slightly lower strength, rigidity, and glass transition temperatures than PET and slightly better impact resistance. It is a mechanically strong material with good resistance to solvents and high heat.

Valox is a brand name (PBT/PET) which offers formulations that include performance matched grades designed to provide application specific property profiles. VALOX resins combine heat and chemical resistance, as well as outstanding electrical properties with exceptionally good processability and surface appearance.

Polypropylene is a thermoplastic, low cost polymer with good thermo-resistance and mechanical properties. It is used in a wide variety of applications across many industries due to its durability.

ABS, or acrylonitrile butadiene styrene, is known for its toughness and high impact resistance.

Polycarbonate is a durable material with high impact resistance and low scratch resistance. It’s ideal for lens and clear optical applications and is a good electrical insulator with excellent heat resistance and flame retardant properties.

Makrolon is a brand name material that has glass-like transparency, high dimensional stability, high impact resistance, even at low temperatures, and excellent heat resistance.

Lexan is a brand name high engineered polycarbonate widely used within the plastic injection molding industry.

Acrylic is a tough and lightweight material with excellent optical clarity. It’s typically used as a durable replacement for glass in lens applications. It has great shatterproof and weatherability properties and is resistant to sunlight.

Polystyrene is a general purpose material that is clear, hard, and somewhat brittle. It is an inexpensive resin per unit weight that can produce high performance products in different blends.

Noryl is a brand family of modified resins that are of amorphous blends of Polyphenylene Oxides (PPO) or polyphenylene ether (PPE) resins with polystyrene. Inherent properties include high heat resistance, excellent electrical insulation, and good dimensional stability and processability.

Acetal polyoxymethylene (POM) is among the strongest and stiffest of thermoplastics with low friction and excellent dimension stability.

PEI, amorphous thermoplastic polyetherimide offers outstanding elevated thermal resistance, high strength and stiffness, and broad chemical resistance.

ULTEM is a widely used brand name and is a long term heat resistant material with excellent stability of physical and mechanical properties at elevated temperatures.

Liquid-crystal polymers (LCPs) are a class of aromatic polymers. They are extremely unreactive and inert and highly resistant to fire.

LCP Vectran is a brand name known for its thermal stability at high temperatures, high strength, and good chemical stability. They are moisture resistant and generally stable in hostile environments.

Polylactic Acid or polylactide (PLA) is a biodegradable and bioactive thermoplastic polyester derived from renewable biomass, typically from fermented plant starches.

Thermoplastic Elastomers (TPE), frequently referred to as thermoplastic rubbers, are a class of copolymers, which are physical mixes of different polymers (usually a plastic and rubber) that consist of materials having both thermoplastic and Elastomeric properties.

Santoprene is a widely used brand of TPE that has excellent chemical and temperature resistance with good flexibility, dimensional stability, and long term aging durability.

Neoprene, also polychloroprene, is a family of synthetic rubbers with good chemical stability and flame resistance with flexibility over a wide temperature range.

Aztec Plastic is on the cutting edge of plastic injection molding, 3D printing, and machining and secondary services. Whatever your project or product, we will find the thermoplastic or thermoset materials that will produce the best results possible.

| Torlon | Makrolon |

| PEEK | LCP Vectran |

| Nylon | Valox |

| Polypropylene | Acetal |

| Acrylic | PBT |

| Polycarbonate | Polyethylene |

| Ultem | Polystyrene |

| PVC | Noryl |

| ABS | Lexan |

| Thermoplastic Elastomers |

Services we offer for other materials

Assembly —Fastening, physical joining, adhesives application, sonic welding, hot stamping.

Centerless and Cylindrical Grinding —Tight tolerance diameters / roundness

Contract Manufacturing —Blanket POs, Batch quantities, Just in Time Inventory

Machining — Cutting, Turning, Milling, Grinding.

Plastic Injection Molding —Specialty high performance molding, Plastic injection over molding, and Insert molding.

Prototyping and 3D Printing —Low Volume Machining and Molding