Plastic Prototyping and 3D Printing

We help you test products before production

- Reduce overall production costs

- Create prototypes fast, in hours rather than weeks

Plastic prototyping

Using state-of-the-art equipment, Aztec Plastic creates detailed prototypes from a wide variety of plastics, depending on the requirements for the product in development. A plastic injection molding prototype mold is extremely important for a new product, offering a fast, low cost tooling solution for parts testing.

Plastic prototyping lowers costs by allowing our customers to inspect, test, and scrutinize finished products, tweaking and resolving all details to ensure the best possible outcome, without the high cost of a full production run. When testing the capabilities of a new product design or feature, it is important to put both the functionality and design to the test to ensure its viability.

Benefits of our plastic prototyping process

- Building prototypes reduces the overall costs of a project.

- Rapid plastic prototyping takes hours, rather than weeks, allowing for quick testing.

- Plastic prototyping is possible with a variety of plastica and colors to test not only functionality, but aesthetics, too.

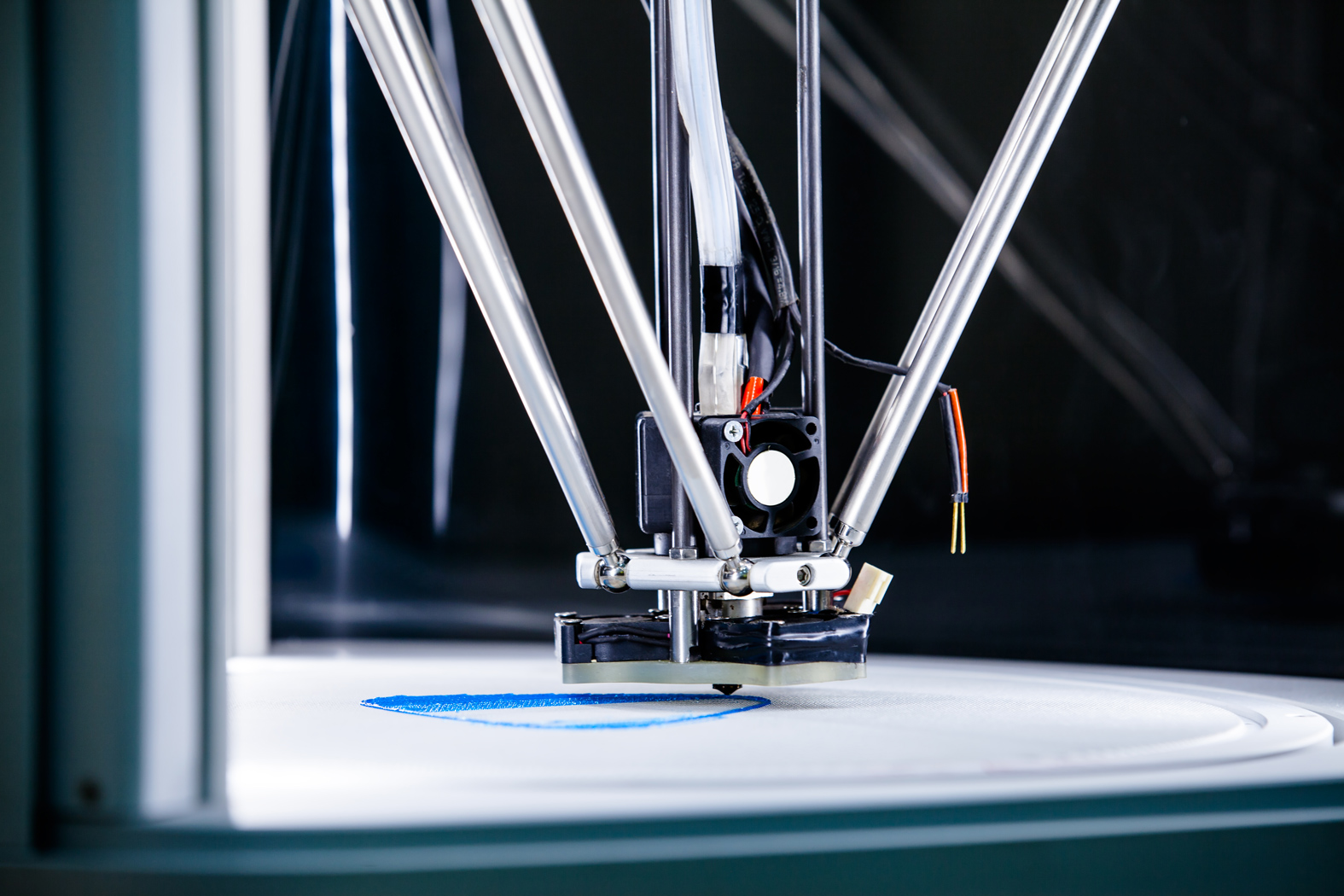

Plastic 3D printing

3D printing is an additive manufacturing process that turns digital design files into functional, three dimensional objects. Items can be printed in a variety of materials such as prototyping plastic, transparent plastic, rubber like plastic, high detail resin, and many others.

Though the 3D printing process has been used in industrial applications since the early 1980s, it only recently skyrocketed in popularity when the Fused Deposition Modeling technology patent expired in 2009. This patent covered one of the most important aspects of 3D print. Introduction of the patent to the public domain enabled vital and rapid innovations to be made while greatly reducing the price of 3D printers and 3D printing software. This progress allowed a once expensive process to be more accessible and affordable to both large and small businesses.

As the industry progresses, the applications for three dimensional printing are only limited by the designers’ imaginations. 3D Printing has nearly infinite applications, including rapid prototyping, architectural models, forensic pathology, film and television production, fashion, custom prosthetics, medical devices and much more.