High Quality Thermoplastic Polymers

High strength, sustainable component solutions

- Lightweight, strong plastics

- Temperature and chemical resistance

- Perfect for injection molding

Thermoplastic polymers are one of the most common industrial plastics used in manufacturing. They are composed of unlinked polymer molecules that have high molecular weight, indicating that when they are cooled to a specific temperature, they have an impressive structural strength and very smooth surfaces. When heated, the thermoplastic polymers will soften and become more elastic, making them ideal for plastic injection molding.

Thermoplastic polymer uses

Types of thermoplastic polymers

Polyethylene — Highly cost effective and very strong, polyethylene has a tensile strength of 4,000 psi, absorbs almost no water, and is resistant to chemicals.

Polypropylene —Rugged with a high chemical resistance, polypropylene is used for packaging and medical equipment and has a tensile strength of 4,800 psi.

Polystyrene —One of the most widely used plastics, polystyrene is commonly used for petri dishes, test tubes, microplates, and other laboratory containers.

Polyvinyl —Dense and hard, polyvinyl (PVC) is put to use in the construction industry, for signs, in the healthcare industry, and as fiber for clothing. It is also very common as electrical wire insulation and for pipes for plumbing.

Polyamides —Also known as nylon, polyamides are commonly used in injection molding to create parts for medical devices, cars, and pumps and is a substitute for low strength metals.

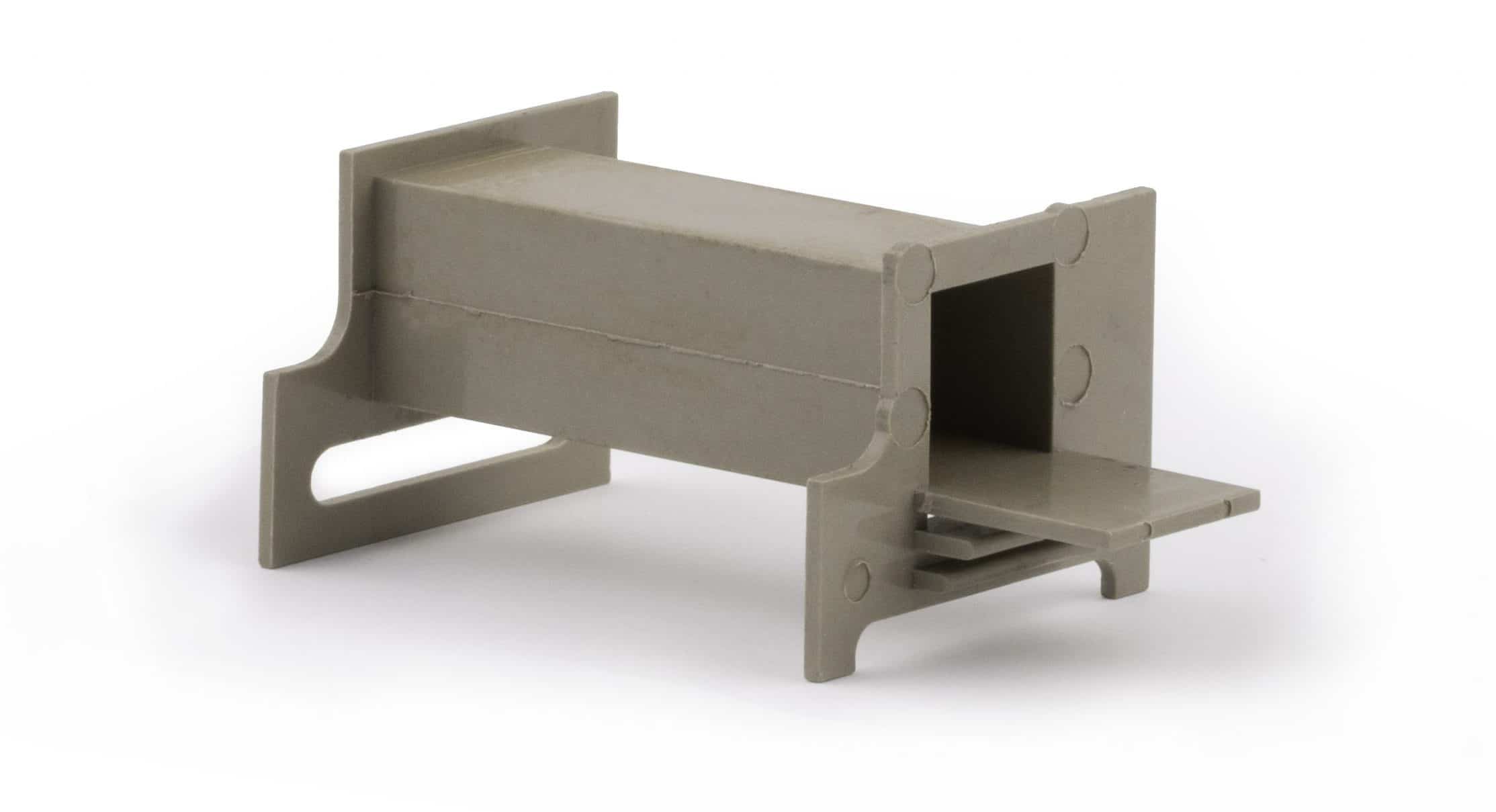

Acrylonitrile butadiene styrene (ABS) —Acrylonitrile butadiene styrene (ABS) is a very common thermoplastic polymer and is ideal for very vigorous critical applications. It is commonly used in part production and 3D-print manufacturing for OEM manufacturers.

Polytetrafluoroethylene (PTFE) —Teflon™ PTFE is a performance thermoplastic known for its chemical inertness, low coefficient of friction, broad operating temperature range, excellent dielectric properties, thermal and electrical insulating, and negligible water absorption.